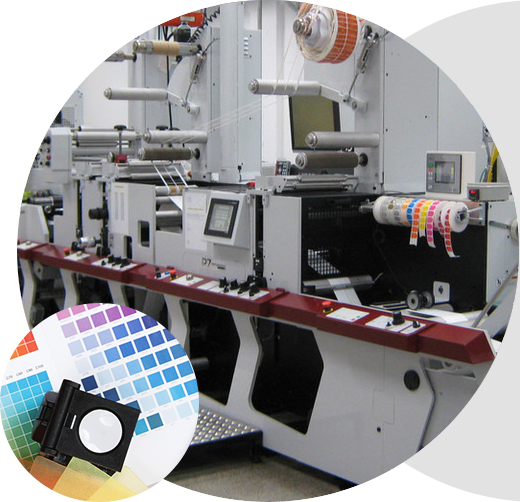

Printing

Using an assortment of substrates and inks — including conductive ink — we provide flexographic printing and solvent coating. Our substrate heat treating and ink technology ensures an exceptionally clean and durable printed surface that can be used on a multitude of products.

With state-of-the-art manufacturing facilities, experienced professionals at every level, and the passion of building innovation for life, we can turn your idea into a reality. Contact us today to explore the virtually endless possibilities Katecho has to offer in contract manufacturing.

.png)