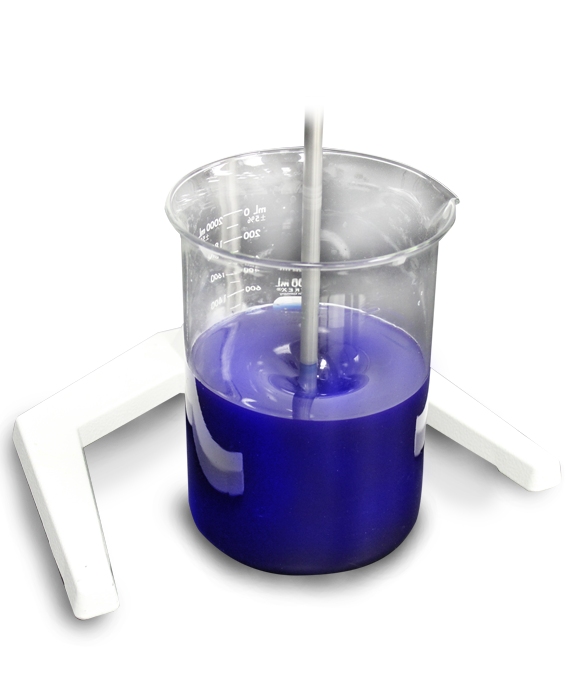

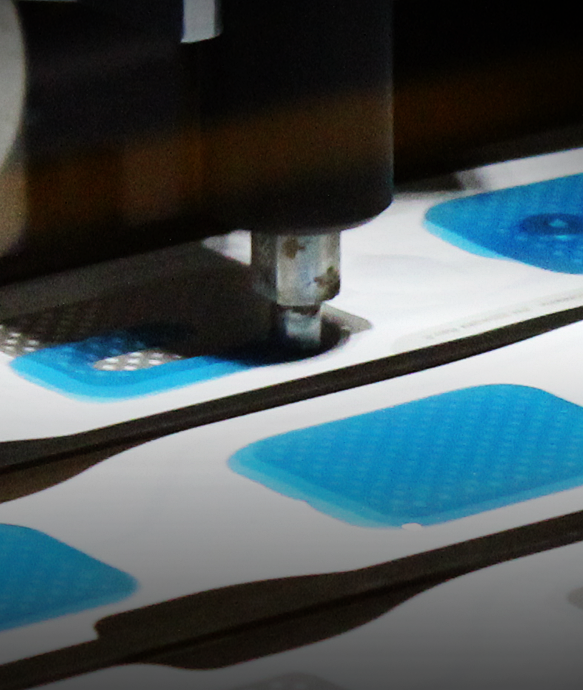

Hydrogel Manufacturing

Katecho is a world leader in designing and manufacturing hydrogels for a variety of applications. We offer a wide range of options for formulating and curing hydrogels, resulting in virtually endless possibilities for hydrogel use. Whether you need hydrogel as a raw material, converted into a subassembly, or assembled directly into a final product, we will work with you to find the right solution.

With state-of-the-art manufacturing facilities, experienced professionals at every level, and the passion of building innovation for life, we can turn your idea into a reality. Contact us today to explore the virtually endless possibilities Katecho has to offer as a hydrogel manufacturer.

.png)